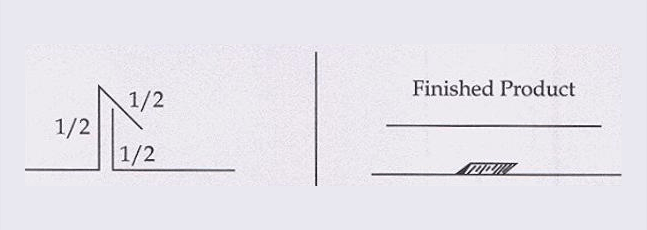

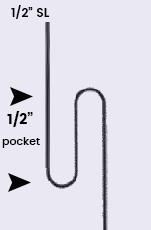

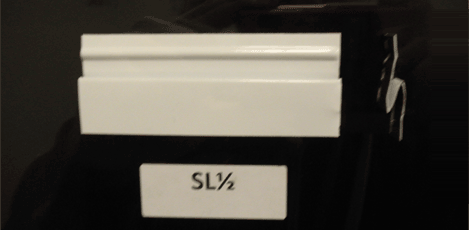

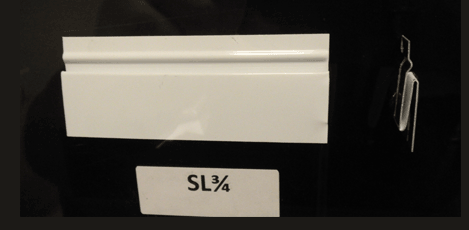

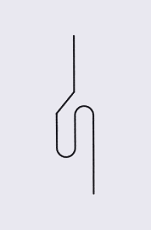

1. SMOOTH LOCK (SL)

- The 1/2” SL uses 2” of metal from the overall cut size.

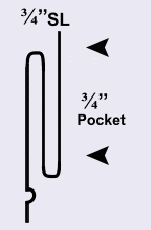

- The 3/4” SL uses 3” of metal from the overall cut size

- The 3/4” SL is user friendly and allows more room for error.

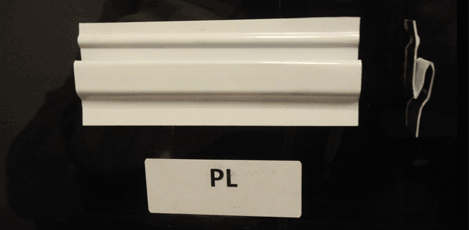

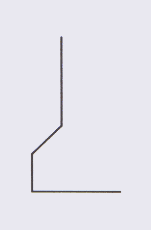

2. PITTSBURGH LOCK (PL)

- The PL uses 2 inches of metal.

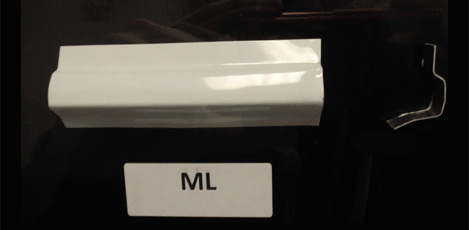

3. MOCK PITTSBURGH LOCK (ML)

- The ML has become more popular over the past few years.

- It is located at the bottom of units, 1″ of material is required to manufacture the ML.

4. NO LOCK (NL)

- This indicates that no lock is needed and just the rough edge is left.

5. HEM LOCK (HL)

- The HL is utilized for pieces which may require a 1/2 inch return to allow the finished edge to be smooth rather than raw. (as is the case when no lock is applied.)

- The standard HL has a 1/2 inch return as it is the minimum amount needed to manufacture the HL, however returns of 3/4″, 1″ etc., are also possible.

6. ROOF LOCK

- Roof lock locks two or more pieces together with only a small seam.